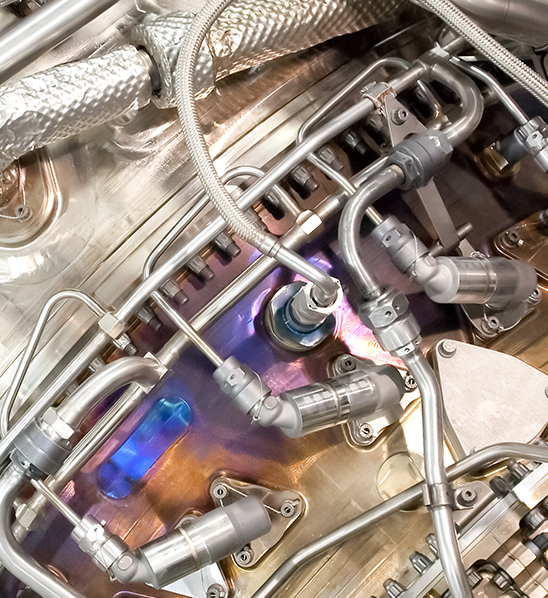

Coolant Thermostat Housing

Information to be updated

The Coolant Thermostat Housing is a key component in the engine cooling system. Typically installed on the engine block or cylinder head, its primary function is to house and secure the thermostat and serve as a flow connection for coolant flow into and out of the engine and radiator. This housing ensures precise control of the coolant flow path.

Product Features:

Serves as a mounting bracket for the thermostat, ensuring it accurately senses coolant temperature and opens and closes as needed.

Directs coolant flow between the engine and radiator for precise temperature regulation.

Constructed from high-strength materials, it withstands high pressure, high temperatures, and corrosion, ensuring long-term sealing and reliability.

Provides a reliable sealing surface (usually with a gasket or seal) to prevent coolant leaks.

Dimensions and connectors strictly adhere to original equipment (OE) specifications, ensuring a perfect fit with the vehicle's cooling system and easy installation.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

English

English Espa?ol

Espa?ol