Industry News

Car modification knowledge: the benefits of changing the exhaust manifold

Car modification knowledge: the benefits of changing the exhaust manifold

Abstract:

The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on its design. […]

The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on its design.

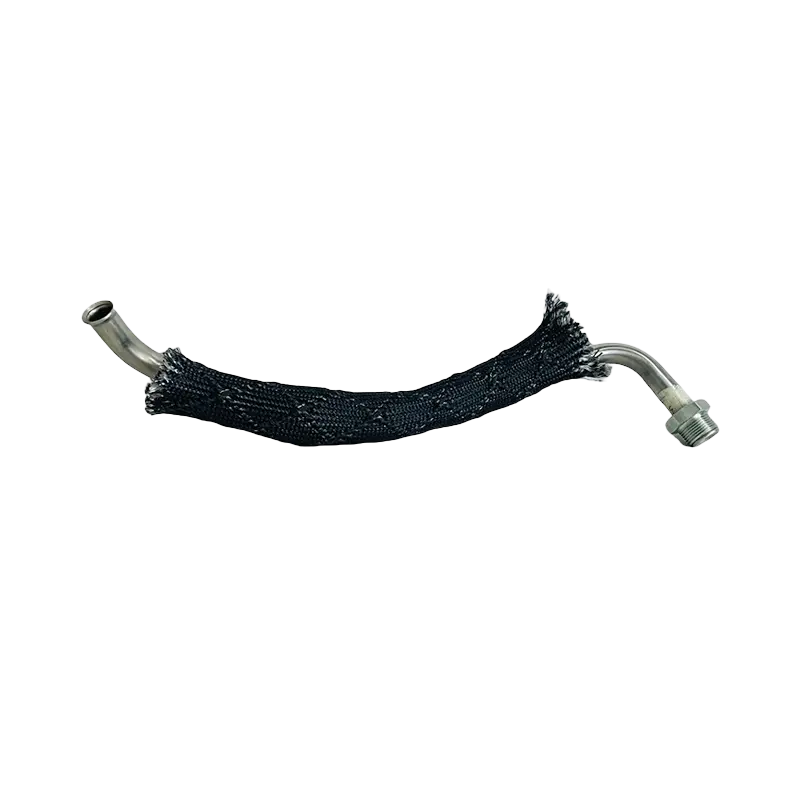

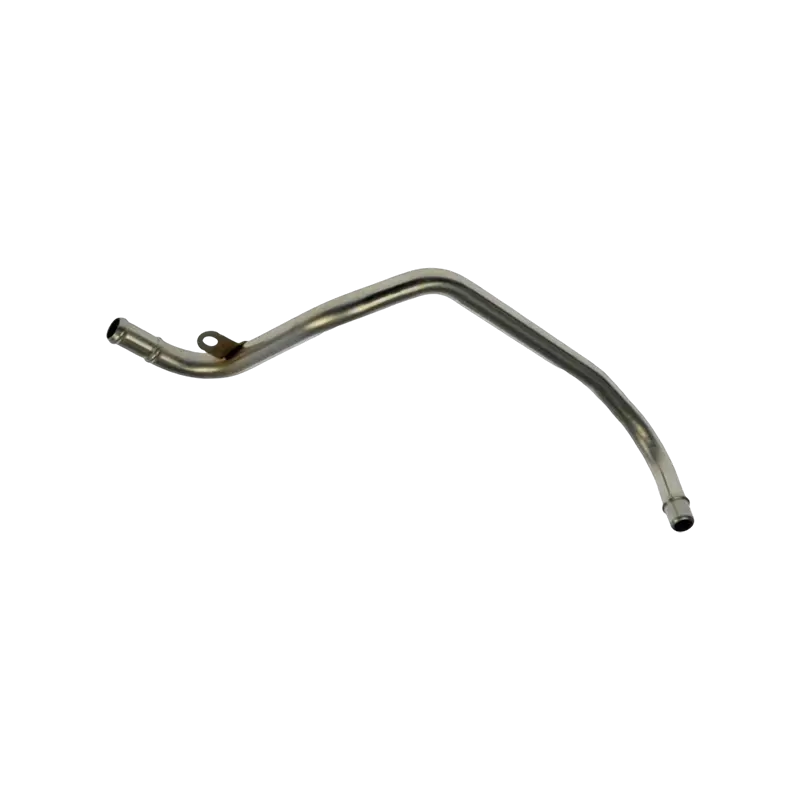

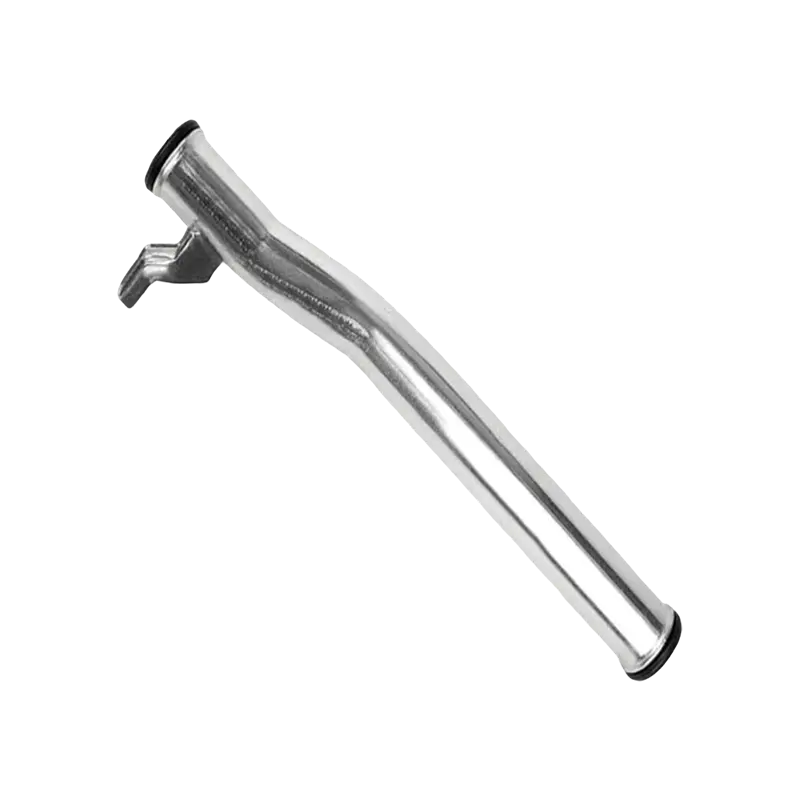

The exhaust manifold consists of an exhaust port mounting bracket, manifold piping, manifold joint, and joint mounting bracket. Exhaust manifolds in conventional vehicles are typically made of cast iron. Their primary drawbacks are weight, durability, and uneven pipe lengths, leading to minor exhaust interference, which significantly reduces exhaust system efficiency.

Secondly, the most critical step in improving exhaust system efficiency is replacing low-performance exhaust manifolds. High-performance exhaust manifolds are made of corrosion-resistant stainless steel. First, the exhaust port mounting brackets of low-quality exhaust manifolds are CNC-machined, resulting in a lower density and preventing leaks. There are two methods for pipe fabrication. Typically, a single pipe is bent and then welded to the mounting bracket. This method offers advantages such as a smoother inner surface, lower exhaust resistance, and reduced weight. However, its disadvantage is that the pipe diameter is less likely to form knots during the bending process, making it easier to achieve a purely uniform exhaust manifold design with both length and curvature. Therefore, welded pipes are cut using a pre-designed mold as a reference, with pipes of varying angles and lengths. Each pipe is welded individually, and the weld marks and inner surfaces are polished to the highest points. While welded exhaust manifolds can achieve a purely uniform design, they require less sophisticated welding techniques and pipe positioning, requiring a thorough inner polishing process to achieve the smoothness of a bent pipe. Consequently, low-quality welded exhaust manifolds are significantly more expensive than bent ones.

The manifold joints are also available in two designs: a 1-in-1 design and a 2-in-1 design. The former prioritizes low-rpm power output, while the latter focuses on high-rpm torque output. The most inefficient exhaust manifold is the multi-in-one design. Typical multi-in-one products feature a relatively straightforward funnel-shaped joint. This disadvantage prevents exhaust gases from all manifolds from mixing evenly before discharge, which can lead to exhaust interference. Therefore, the exhaust manifold developed with a spherical expansion chamber structure, inspired by racing exhaust systems, allows exhaust gases from each manifold to be discharged evenly and smoothly, preventing exhaust interference and significantly improving exhaust efficiency.

In recent years, low-performance exhaust manifolds have also been made of titanium alloy. Titanium alloy's primary advantages are its low strength and low weight. Using very thick thicknesses can achieve strength and weight exceeding that of stainless steel. Consequently, titanium alloy's resistance to heat dissipation decreases, but it offers improved thermal expansion properties, allowing for higher exhaust temperatures and significantly improving exhaust efficiency.

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English Espa?ol

Espa?ol